Episode 2 of Hidden Challenges in Hybrid Solar-Plus-Storage Development series

Executive summary: Solar-plus-storage projects face a critical gap between economic projections and operational reality due to fragmented control architectures, and this post introduces three key challenges that repeatedly compromise performance: multivendor coordination, grid service gaps, and control layer complexity.

In our previous post, we explored the economics and market drivers behind the rapid adoption of hybrid solar-plus-storage projects across the globe. Hybrid projects offer developers access to multiple revenue streams, better capacity factor utilization, and increasingly attractive offtake agreements. It’s no surprise that hybridization has become the default approach for new renewable energy development globally.

In this context, “hybridization” means adding battery storage to solar projects—whether that’s building them together from the start, or adding batteries to existing solar farms. This combination allows operators to store solar energy and dispatch it when it’s most valuable, rather than only generating power when the sun shines. But there’s a gap between the pro forma and operational reality—one that often doesn’t surface until commissioning begins or, worse, after commercial operation starts. A primary focus tends to be on megawatts (MW) and economics during development. Control architecture decisions, however, can make or break project performance.

The Root Issue: Fragmented Control Architecture

A fundamental challenge stems from how hybrid projects have historically been structured. A solar-plus-storage facility isn’t really a single plant—it’s three distinct systems forced to work together:

- Substation controls manage grid interconnection, monitoring voltage and frequency while enforcing interconnection agreement limits.

- Photovoltaic (PV) controls optimize for maximum solar irradiance, managing inverter setpoints, tracker positioning, and string-level performance.

- Battery energy storage systems (BESS) controls prioritize battery protection and cycle life, managing charge/discharge rates, thermal conditions, and state of charge.

Vendors for each system tend to have unique expertise and differentiated capabilities controlling that portion of the plant. BESS control vendors, for example, have control modes designed for bi-directional power flows allowing for high-speed up and down ramping of power flows. PV control vendors, on the other hand, tend to provide less sophisticated power plant controls focused on reactive power or inverter curtailment modes.

In historical or previous project structures, these three systems operate independently, each supplied by different vendors with their own control philosophies and communication protocols. They meet in a DMZ LAN—a demilitarized zone where coordination becomes complex and responsibility becomes ambiguous. The power plant controller (PPC) typically lands with the PV scope owner, but BESS providers are optimized for storage dispatch, not generation forecasting; and PV providers don’t fully understand storage constraints.

The result: finger-pointing during commissioning, coordination headaches during operation, and latency between controllers, leading to compromised performance that erodes the revenue projections that justified the project in the first place.

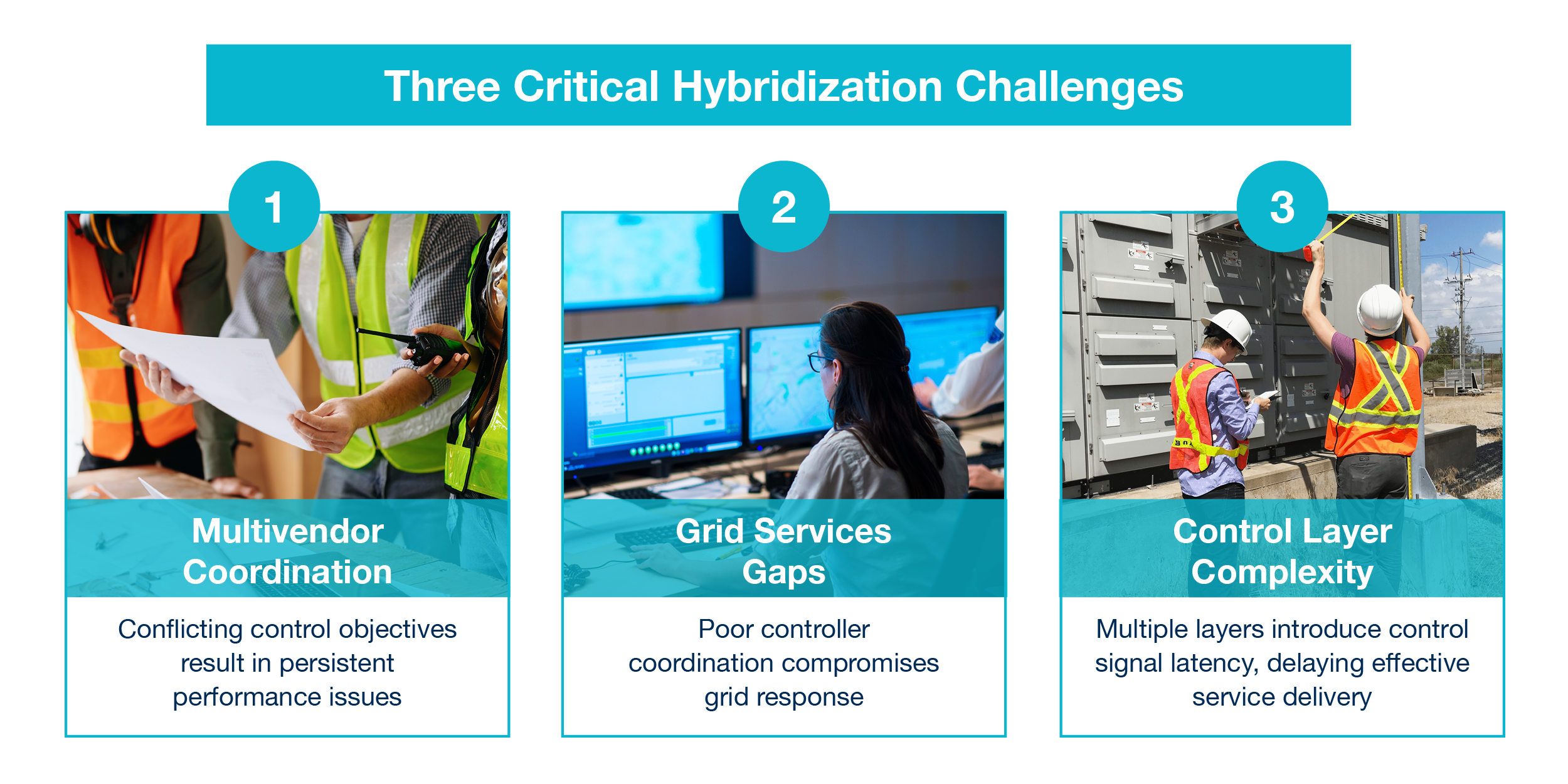

Three Critical Challenges

Over the next three posts, we’ll examine specific control architecture challenges that repeatedly surface in hybrid projects—challenges that are often overlooked during development but become operational and financial liabilities:

- Multivendor Coordination: When PV manufacturers, BESS suppliers, and grid operators each arrive with conflicting control philosophies, integration testing stretches from weeks into months. The coordination gaps don’t disappear at commercial operation date (COD); they create persistent performance issues that reduce availability and degrade grid service delivery.

- Grid Service Gaps: But even when you successfully coordinate multiple vendors, there’s a deeper problem: the control systems themselves weren’t designed for hybrid assets. Traditional PV plant controllers optimize for solar harvest without understanding battery constraints. BESS energy management systems treat solar generation as an external variable they can’t control. Neither was built to deliver grid services that require real-time coordination between both resources.

- Control Layer Complexity: Modern grid operators demand fast frequency response (FFR) within milliseconds. When your EMS and PPC exist as separate systems with multiple handoffs between them, you’ve architected latency into your control system. Assets that should qualify for premium FFR markets fail performance tests—not because the hardware can’t respond, but because the control architecture is too slow.

These challenges are interconnected. Multivendor coordination issues amplify latency problems. Grid service gaps and control signal latency multiply with each additional vendor and communication interface. Latency concerns constrain architectural choices. Address one problem in isolation, and you often make another worse.

Scenarios to Explore

Each post in this series will follow a consistent structure:

- Challenge: The specific technical or organizational issue

- Impact: How it affects commissioning timelines, operational performance, and project economics

- Solution Framework: Architectural approaches that address the root cause

- Key Benefits: What changes when you design with these challenges in mind

- Recommendations for Developers: Actionable guidance to aid conversations with your stakeholders and vendors

Our goal isn’t to claim there’s one perfect solution for every project. Market requirements vary, developer capabilities differ, and risk tolerance spans a wide spectrum. Instead, we want to surface these challenges early—when they can still be addressed through thoughtful architecture decisions rather than expensive retrofits or permanently compromised performance.

Next up — Multivendor Coordination: Why conflicting control philosophies turn two-week integration tests into two-month troubleshooting marathons, and what unified hybrid intelligence looks like in practice.