Executive summary: When PV controllers, BESS suppliers, grid operators, and optimizers have conflicting control objectives, integration testing stretches from weeks into months, eroding project revenue. This post explores how unified hybrid intelligence can eliminate costly coordination gaps.

In our previous post, “Three Control Architecture Decisions That Determine Hybrid Performance”, we explored how fragmented control architectures create hidden challenges in solar-plus-storage projects. Traditional hybrid developments combine three independent systems—substation, photovoltaic (PV), and battery energy storage system (BESS) controls—each from different vendors with their own control philosophies. They meet in a DMZ LAN where coordination becomes complex and accountability becomes ambiguous.

Over this series, we’re examining three critical challenges: multivendor coordination, grid services gaps, and control layer complexity. Today, we start with the coordination problem that turns straightforward integration into months-long troubleshooting exercises.

Challenge

Multivendor Coordination

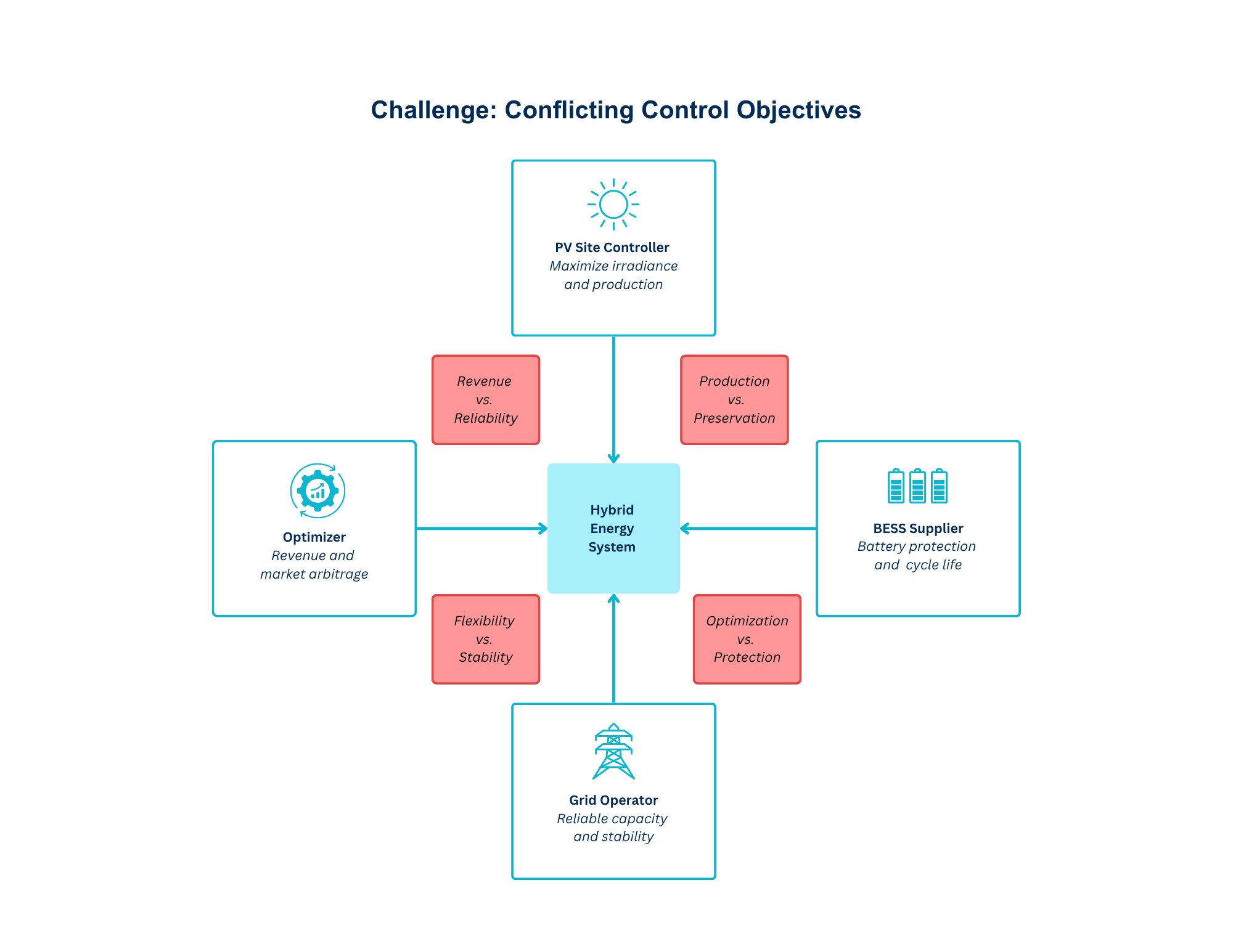

Conflicting Control Objectives

A typical hybrid project combines multiple parties who each have different priorities:

- The PV site controller optimizes for maximum irradiance and production

- The BESS supplier prioritizes battery protection and cycle life

- The grid operator demands reliable capacity

- The optimizer/direct marketer maximizes revenue through market arbitrage and dispatch optimization

Each arrives with their own control objectives, communication protocols, and performance assumptions. The optimizer and grid operator often have competing priorities: the optimizer responds to price signals to maximize revenue through aggressive dispatch strategies, while the grid operator needs predictable, reliable power and capacity within operational restraints. In practice, the optimizer may command maximum output when prices spike, but the grid operator ultimately controls market access by approving or curtailing that bid based on grid needs. When the optimizer’s revenue-maximizing setpoint conflicts with the grid operator’s approved capacity limit, the power plant controller receives competing signals. The power plant controller must continuously reconcile these different setpoints—determining which takes priority based on the established control hierarchy. The result is potential for conflicting setpoints and coordination gaps between the optimizer and the grid operator.

Impacts

Integration Complexity Becomes an Operational Tax

Integration testing that could have been scoped for two weeks can stretch into two months while engineers troubleshoot communication errors and conflicting control logic, pushing COD and directly eroding the project’s NPV.

The problem doesn’t end once the project is operational; after COD, the coordination gaps create persistent performance issues. Consequently, assets spend more time offline for troubleshooting and encounter miscommunication that results in improper setpoints or delayed responses to grid signals. As a result, revenue suffers through reduced availability, missed dispatch opportunities, and degraded grid service performance.

Revenue suffers through reduced availability, missed dispatch opportunities, degraded grid service performance, and suboptimal market participation when the optimizer can’t access the asset’s true operational flexibility.

Solution Framework

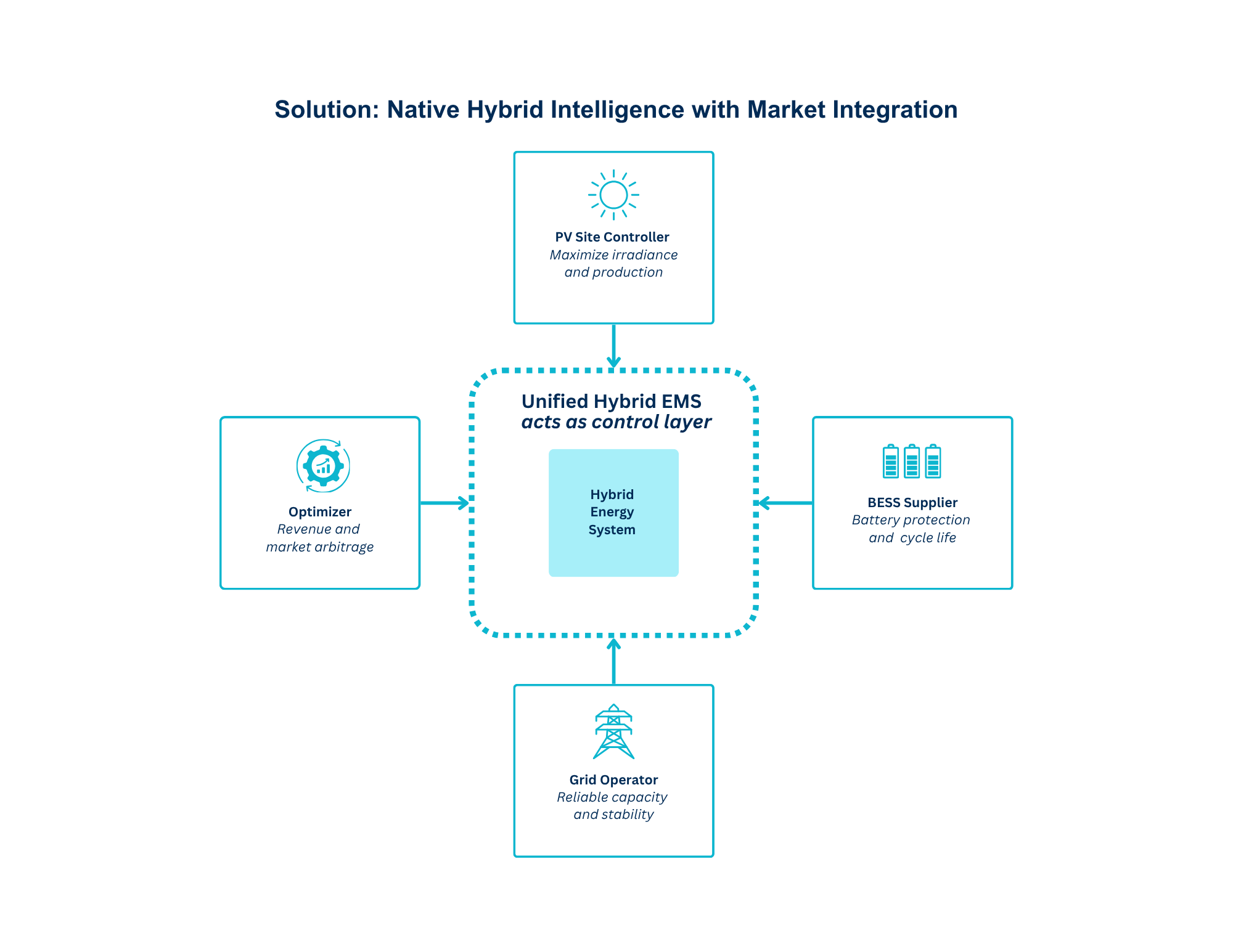

Native Hybrid Intelligence with Market Integration

A unified hybrid EMS approaches the problem differently: rather than forcing separate PV and storage control systems to coordinate through communication layers, it natively understands both resources as parts of a single hybrid asset.

The EMS operates from singular logic that simultaneously considers solar variability, battery state of charge, degradation curves, and grid requirements. This eliminates the translation layer between control philosophies entirely.

Key Benefits

Accountability and Architecture

Single vendor accountability means clear ownership when performance issues arise—and no more finger-pointing between PV and BESS suppliers over who’s responsible for coordination failures. The purpose-built integration architecture reduces commissioning time and technical risk during the critical path to COD. Long-term, operators gain a control system designed specifically for hybrid complexity rather than retrofitted from standalone solar or storage logic.

Key Takeaways & Recommendations for Developers

Evaluate control architecture as a strategic decision during vendor selection by:

- Select a controls integrator as early in the project life as possible to reduce revenue loss, avoid commissioning delays and integration challenges, and more.

- Requesting detailed system architecture diagrams showing how PV and BESS coordination actually works (separate controllers connected by communication protocols indicate multivendor complexity)

- Establishing single-point accountability for hybrid performance in contracts, not just component-level specifications

- For multivendor approaches, conducting factory acceptance testing simulating conflicting control scenarios before equipment ships to site

- Factoring coordination complexity into both commissioning timelines and long-term O&M budgets

Next up: Beyond organizational complexity, there’s a deeper technical issue: control systems themselves weren’t designed for hybrid assets. Traditional PV plant controllers lack the logic to coordinate battery dispatch logic, while BESS systems treat solar as an external variable rather than an integrated resource. In our next post, we’ll explore how this compromises grid service delivery during critical grid events and ramp periods.