In the rapidly evolving battery energy storage system (BESS) market, one of the most critical architectural decisions developers face is how to integrate their battery systems: with an AC-coupled or DC-coupled configuration. Neither approach is inherently better; rather, the optimal choice depends on the specific goals of the project, site constraints, and revenue strategies.

Over the past 16 years, Stem has operated more than 760 AC-coupled sites totaling 1.4 GWh of capacity, alongside 16 DC-coupled sites totaling 157 MWh. This disparity isn’t due to operational constraints–Stem has deep expertise in both architectures–but reflects broader market realities: DC-coupled systems are often more complex and costly to implement, particularly in retrofit scenarios or sites with limited design flexibility. As a result, many developers gravitate toward AC-coupled configurations for their modularity and ease of deployment.

In this edition of Battle of the BESS, we examine the technical trade-offs, market dynamics, and operational considerations that shape coupling strategies in today’s competitive landscape.

What’s the Difference Between AC- and DC-Coupling?

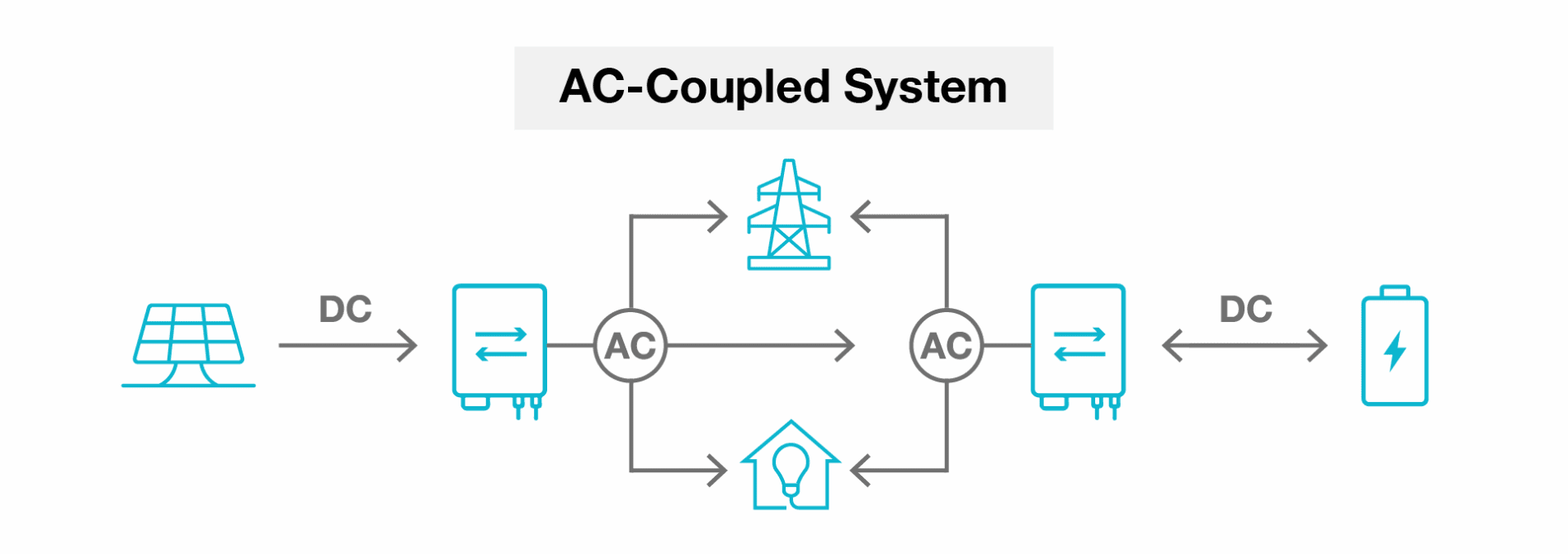

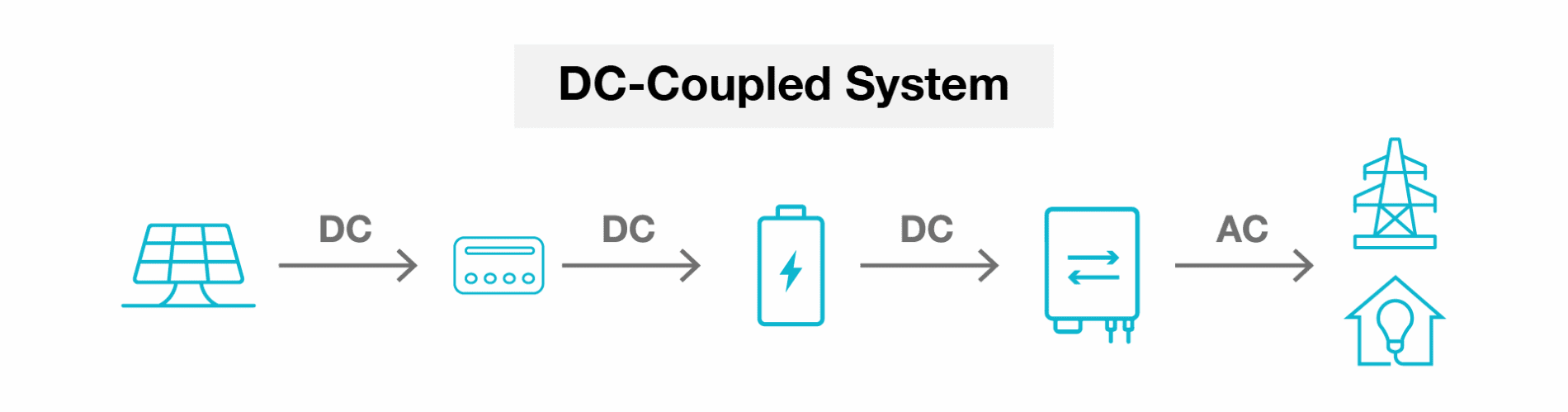

AC- and DC-coupling refer to the point at which a battery system connects relative to the inverter. In an AC-coupled setup, batteries and PV are connected to the grid via their own dedicated inverter(s), allowing each to operate independently. DC-coupled systems, on the other hand, share an inverter between the solar array and battery, enabling the battery to charge directly from solar on the DC side, achieving higher charging efficiencies.

So, when should developers choose one over the other?

The answer depends on a range of factors, from site layout and interconnection strategy to energy offtake models and solar co-location requirements. The table below outlines key considerations to help developers determine which system architecture best aligns with their project needs.

| Category | AC-Coupled | DC-Coupled |

| When to Use It | Sites that are:

|

Sites that are:

|

| Solar Co-Location |

|

|

| Charging Efficiency[d] |

|

|

| Interconnection Complexity |

|

|

| Flexibility with Solar Retrofits |

|

|

| Market Participation |

|

|

| CapEx Considerations |

|

|

Understanding Coupling Fundamentals

The coupling decision fundamentally shapes how energy flows through a storage system.

In AC-coupled configurations, solar panels and batteries maintain electrical independence, each with dedicated power conversion equipment. This architecture enables batteries to charge from the grid during low-price periods while simultaneously exporting solar generation. Such operational flexibility can prove valuable in dynamic electricity markets.

In contrast, DC-coupled systems create a more integrated architecture where batteries share the solar plant’s inverter infrastructure. This design enables direct DC-to-DC charging from solar panels, eliminating one conversion stage and its associated 2-4% energy losses.[1][2]

Solar Co-Location Dynamics

The relationship between solar generation and battery storage differs dramatically between coupling approaches. DC-coupled systems excel at capturing energy that would otherwise be lost to inverter clipping when solar arrays are oversized relative to inverter capacity.[3] Industry data shows systems with 1.5:1 DC/AC ratios can recover 90% of clipped energy through DC-coupled storage, translating to approximately 5% additional annual energy capture.[4]

This clipping recovery capability has proven particularly valuable as developers increasingly oversize arrays.[5] A Massachusetts SMART program analysis demonstrated DC-coupled systems capturing over 265 MWh of additional clipped solar energy annually in a 3MW PV/1MW storage configuration, generating approximately $1.5 million in additional annual revenue.[6]

AC-coupled systems sacrifice this clipping recovery capability but gain locational flexibility. Batteries can be situated away from solar arrays, near substations or load centers, simplifying construction logistics and enabling phased development strategies. This flexibility proves especially valuable in retrofit applications where available space near existing solar infrastructure may be limited.

Efficiency Metrics and Real-World Performance

When charging directly from solar, DC-coupled systems achieve 95–98% efficiency, thanks to single-stage DC-DC conversion. [7] Grid charging, however, lowers that figure to about 87% due to added conversion. [8] AC-coupled systems, while less efficient overall, offer more consistent performance across charging sources.

While they differ in efficiency, temperature effects, partial load operations, and battery state-of-charge variations affect both architectures similarly. Modern battery management systems optimize charging profiles to maintain efficiency, though DC-coupled systems’ distributed battery placement can complicate thermal management compared to centralized AC-coupled installations.

Interconnection Complexity and Grid Integration

Grid interconnection represents one of the most significant project development challenges, with coupling choice substantially affecting complexity and costs. DC-coupled systems simplify the utility interface through a single point of common coupling, reducing interconnection study costs by $50,000-150,000 compared to systems requiring multiple connection points.[9]

However, this integration creates dependencies. Modifications to DC-coupled systems require comprehensive electrical reassessment since removing the storage component affects the entire plant’s electrical design. AC-coupled systems, however, maintain design independence–storage can be added, removed, or modified without affecting the solar plant’s operations.

FERC’s (Federal Energy Regulatory Commission’s) Order 2023 reforms have introduced cluster study processes and hybrid resource classifications that somewhat level the playing field.[10] Both coupling approaches can now share interconnection capacity more effectively, though AC-coupled systems retain advantages in markets requiring fast frequency response or independent capacity demonstrations.

Retrofitting Existing Solar Installations

The retrofit market has emerged as a key battleground for coupling technologies, with battery attachment rates rising from 6% in 2020 to 25% by early 2024.[11] AC-coupled systems dominate this segment, capturing 60-70% of retrofit installations due to their minimal disruption to existing operations.[12]

Retrofitting DC-coupled storage requires proximity to existing inverters and often necessitates equipment replacement–a significant barrier given typical 10-year solar inverter warranties. The installation disruption and potential loss of existing equipment warranties make DC-coupled retrofits economically challenging unless timed with planned inverter replacements.

Market Participation and Revenue Optimization

The differences in operational flexibility between coupling approaches significantly affect revenue generation potential. AC-coupled systems excel in frequency regulation markets, providing Regulation D services in PJM or participating in CAISO’s regulation up/down markets without solar generation constraints. This independence enables 24/7 ancillary service provision and superior value stacking across multiple revenue streams.

DC-coupled systems face operational constraints during simultaneous solar generation and grid service provision due to shared inverter capacity. However, they capture unique value through clipping recovery and higher efficiency energy arbitrage. This could lead to reaching your ROI sooner compared to the equivalent AC-coupled system when optimizing for energy arbitrage.

It’s important to note that market saturation trends affect optimal strategies. Over the past few years, energy arbitrage has become the dominant revenue stream, representing 60% of storage market activity in major ISOs–a trend favoring DC-coupled efficiency advantages.[13]

In short, AC-coupled systems shine in ancillary services and multi-market participation while DC-coupled systems excel in energy arbitrage and maximizing solar yield. Your optimal choice depends on the revenue stack you’re prioritizing.

Capital Cost Considerations and Warranty Management

Recent industry analysis reveals DC-coupled systems achieve 10-20% lower capital costs through shared infrastructure and reduced equipment needs.[14] The elimination of separate battery inverters saves in power electronics costs, though this is partially offset by DC-DC converter requirements.

In addition, installation costs differ between the two system types significantly: DC-coupled systems require 10-15% of total project cost for installation versus 15-20% for AC-coupled systems.[15] However, DC-coupled installation complexity requires specialized expertise and can extend project timelines compared to modular AC-coupled approaches.

Warranty structures present distinct trade-offs. DC-coupled systems typically feature integrated warranties covering the entire hybrid system, simplifying administration but creating single-vendor dependencies. AC-coupled systems require coordination across multiple equipment suppliers but enable selective component upgrades and reduce single-point-of-failure risks.

Evolving OEM Landscape and Technology Trends

The market has witnessed significant consolidation and strategic shifts over the past several years. Many OEMs have phased out dedicated DC-coupled products in favor of AC-coupled systems that serve broader markets and offer greater design flexibility. This transition reflects a combination of technical integration challenges, installer preferences, and evolving policy and market dynamics.

One of the key drivers behind the earlier adoption of DC-coupled systems was the structure of legacy federal tax incentives. Under previous versions of the Investment Tax Credit (ITC) and Production Tax Credit (PTC), batteries needed to charge at least 75% of their energy from on-site solar generation to qualify—pushing developers toward DC-coupled systems with higher charging efficiency.[16] However, recent changes to tax policy have decoupled these requirements, enabling standalone storage and distributed energy storage systems (ESS) to qualify independently.

This shift has opened the door for AC-coupled architectures to gain broader traction, particularly for non-solar applications and hybrid assets optimized for grid services.

Conclusion

Today, neither AC- nor DC-coupling represents a universally superior solution. DC-coupled systems continue to excel in greenfield solar + storage projects with high DC/AC ratios and use cases prioritizing energy capture efficiency. The ability to recover clipped energy and maximize round-trip efficiency creates compelling value in arbitrage-driven revenue models.

Conversely, AC-coupled systems dominate retrofit markets, standalone storage deployments, and projects requiring operational flexibility and modular scalability. Their ability to provide grid services independently of solar generation–along with simplified permitting, proven reliability, and broader OEM support–makes them the preferred choice for value stacking across multiple market products.

As storage markets mature and revenue strategies evolve, the coupling decision increasingly hinges on project-specific factors rather than categorical advantages. Developers must weigh site constraints, interconnection pathways, financing structures, and operational goals to determine the most appropriate system architecture.

The continued advancement of power electronics, policy frameworks, and hybrid system designs suggests that both coupling approaches will remain relevant in the expanding BESS ecosystem–each well-suited to distinct use cases where their inherent strengths can be fully leveraged.

If you have more questions about which configuration is right for you, reach out to us on our website stem.com!

References

[1] Siddiqui, M. U. (2024, June 3). What’s the difference between a DC and AC-Coupled storage system? eCactus Solar. https://ecactussolar.co.uk/difference-dc-ac-coupled-battery-storage-system/

[2] Lo Franco, Francesco & Morandi, Antonio & Raboni, Pietro & Grandi, Gabriele. (2021). Efficiency Comparison of DC and AC Coupling Solutions for Large-Scale PV+BESS Power Plants. Energies. 14. 4823. 10.3390/en14164823.

[3] Staff, A. (2025, July 23). Solar inverter sizing: Choose the right size inverter. Aurora Solar. https://aurorasolar.com/blog/choosing-the-right-size-inverter-for-your-solar-design-a-primer-on-inverter-clipping/

[4] Staff, A. (2025, July 23). Solar inverter sizing: Choose the right size inverter. Aurora Solar. https://aurorasolar.com/blog/choosing-the-right-size-inverter-for-your-solar-design-a-primer-on-inverter-clipping/

[5] Team, J. M. a. T. S. M. A. (2018, November 5). A battery for hire: AC vs. DC coupling for solar + energy storage projects. A battery for hire: AC vs. DC coupling for solar + energy storage projects. https://blog.fluenceenergy.com/energy-storage-ac-dc-coupled-solar

[6] Energy-Storage.News. (2021, August 9). Go big, go DC: an in-depth look at DC-coupled solar-plus-storage. https://www.energy-storage.news/go-big-go-dc-an-in-depth-look-at-dc-coupled-solar-plus-storage/

[7] Safe, NonToxic LiFEPO4 Home Solar Battery – BSLBATT. (n.d.). https://www.bsl-battery.com/. https://www.bsl-battery.com/news/dc-or-ac-coupled-battery-storage-how-should-you-decide

[8] Fields, S., & Marsh, J. (2023, May 19). AC vs. DC Solar Battery Coupling: What you need to know. EnergySage. https://www.energysage.com/energy-storage/ac-vs-dc-solar-battery-coupling-what-you-need-to-know/

[9] Pollak, C. (2021, September 22). Adding energy storage to existing renewable energy assets. ICF. https://www.icf.com/insights/energy/add-energy-storage-renewable-assets

[10] Howland, E. (2023, July 28). FERC issues rule to speed grid connections for storage, renewables, other generators amid 2-TW backlog. Utility Dive. https://www.utilitydive.com/news/ferc-interconnection-rule-queue-renewable-energy/689289/

[11] Lozanova, S. (2025, June 25). Can you add batteries to an existing solar system? GreenLancer. https://www.greenlancer.com/post/adding-batteries-to-an-existing-solar-system

[12] Solar, D. (2025, April 10). Expert Insights: Upgrading Utility-Scale PV Projects with Battery Energy Storage Systems » Detra Solar. Detra Solar. https://detrasolar.com/expert-insights-upgrading-utility-scale-pv-projects-with-bess/

[13] Mathrani, A. (2025, March 18). Battery energy storage systems: The foundations of a resilient energy future in the US – Rabobank. Rabobank. https://www.rabobank.com/knowledge/d011469763-battery-energy-storage-systems-the-foundations-of-a-resilient-energy-future-in-the-us

[14] Opie, N. (2023, April 24). AC vs DC-coupled BESS: the pros and cons. RatedPower. https://ratedpower.com/blog/ac-vs-dc-coupled-bess/

[15] AC vs DC-coupled BESS: What’s The Difference?-Blog-Suzhou Hisenpower Co.,Ltd. (n.d.). https://www.hisenpower.com/Blogs/ac-vs-dc-coupled-bess-what-is-the-difference

[16] Are investment tax credit changes in store for energy storage? (2021, June 10). https://www.morganlewis.com/pubs/2021/06/are-investment-tax-credit-changes-in-store-for-energy-storage?utm_source=chatgpt.com