Your electricity bill just rose by up to 11%. Here’s why.

Food processors across California may have noticed another increase in their electricity bills this year, as energy providers recently raised rates by up to 11 percent. What isn’t as noticeable is that these rate hikes only affect one specific part of the bill. Here’s what you need to know to combat rising costs.

Demand Charges Are Increasing

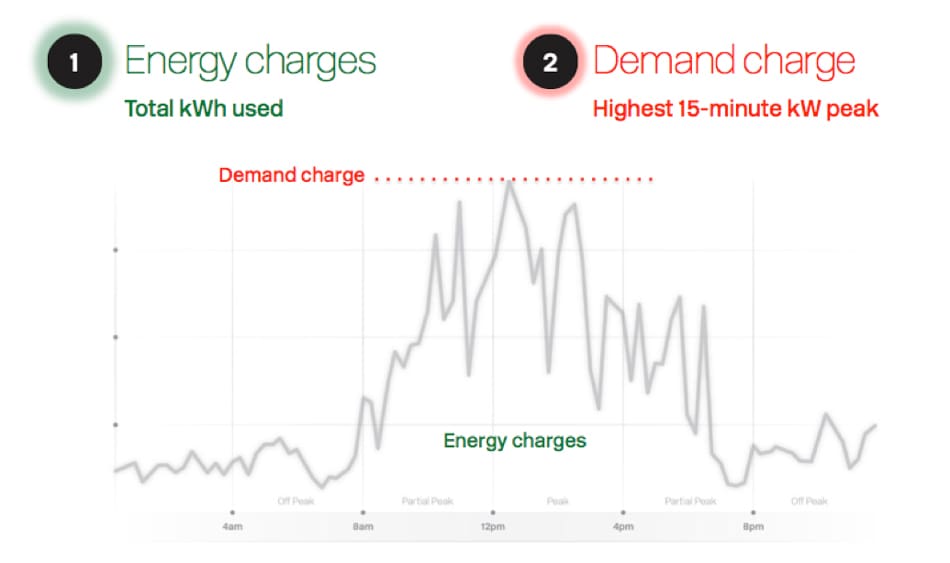

Commercial electricity bills are made up of various charges. ‘Energy charges’ are based on the total amount of energy consumed each month, while ‘demand charges,’ the lesser-known part of the bill, are based on the maximum power required by the facility at a single point in time each billing cycle.

Demand charges often make up more than 50 percent of a typical food processing facility’s electricity costs, and these rates continue to rise. Demand rates have increased by an average of more than 75 percent over the last decade.

Due to factors such as inexpensive natural gas and widespread adoption of renewables, the cost of producing energy has actually declined or stayed flat in recent years. As a result, energy charges have largely trended down, while the cost to deliver that energy has stayed the same or even increased, due to aging infrastructure and capacity constraints. This means that energy providers must increase demand rates to make up for lost revenue and cover fixed costs.

![[stem]-Demand-Charges-Rising-2](https://www.stem.com/wp-content/uploads/2015/04/stem-Demand-Charges-Rising-2.jpg)

This is reflected in rate data, which shows that average energy charges went down by more than 30 percent in the last 10 years, while demand charges have gone up by more than 75 percent. This leaves demand charges as an even larger part of most food processors’ electricity bills.

Energy Efficiency Won’t Eliminate Costly Demand Peaks

Many facilities have attempted to lower their electricity bills with energy efficiency initiatives such as LED lighting, motor or pump upgrades, or improved insulation. While these help lower overall energy consumption, they do not eliminate costly peaks. In fact, until now, there has been little to nothing that can be done to control the one part of your bill that has consistently become more expensive.

Fortunately, advanced technologies are now available that allow food processing facilities to control demand charges by combining powerful energy analytics and energy storage to automate savings.

Companies like ShoEi Foods USA and Safeway have implemented advanced energy storage in order to:

- Save money by automatically trimming energy peaks with no change to operations

- Receive valuable alerts to shift energy use away from moments when costs are highest

- Accurately estimate electricity bills before they arrives

- Visualize how and when they use energy to identify hidden waste

- Assess the impacts of operational changes for better informed decisions

As the leading provider of advanced energy storage to food processors, Stem lowers monthly energy bills with no change to business operations. Stem does more than just store and deploy – it learns your facility’s patterns to maximize savings and deliver real-time, actionable insights. Getting started is easy, with simple activation and no upfront costs.

Combat rising demand charges with Stem.

See if you qualify today.

Tell us a little about yourself and a Stem representative will follow up with you shortly.